Transforming Metal with Unparalleled Expertise

“Crafting Strength and Precision: The Art of Metal Fabrication”

Who we are

Company Background.

Extreme Metal Technology Sdn Bhd was perform marketing solution as well one stop supply chain solution on Sheet Metal Fabrication, Precision Machined Components, Frame & Structure, Tool Design, Jig & Fixture, Laser Engrave Service and others. Provision of Related Services such as perform design & development and value added for sub module assembly services. We are able to deliver innovative solutions that offer the greater flexibility with experienced in-house design team & advanced manufacturing capabilities. Extreme Metal Technology Sdn Bhd perform business support on various of market segments, such as semiconductor, medical devices, instrumentation, telecommunication, Oil & Gas, Aerospace and etc.

Our Mission

To be market leader & excellent provider of engineering solutions by delivering exceptional related value-added services to worldwide customers.

Our Vision

One stop engineering solutions provider from design and development to product delivery with core competencies in metal fabrication, precision machining and other related service with excellent quality as well pricing competitiveness.

QUALITY ASSURANCE

Providing Confidence

Quality by Meet Specified

Requirement

COST EFFICIENCY

Perform Cost Efficiency

without Hindering Quality of

Products

ON TIME DELIVERY

Goods Delivery within

Promised / Required

Date (JIT)

RESPONSIVENESS SERVICE

Provide prompt

response service with

technical support

Services

“High-Quality Metal Fabrication Services for Your Specific Needs”

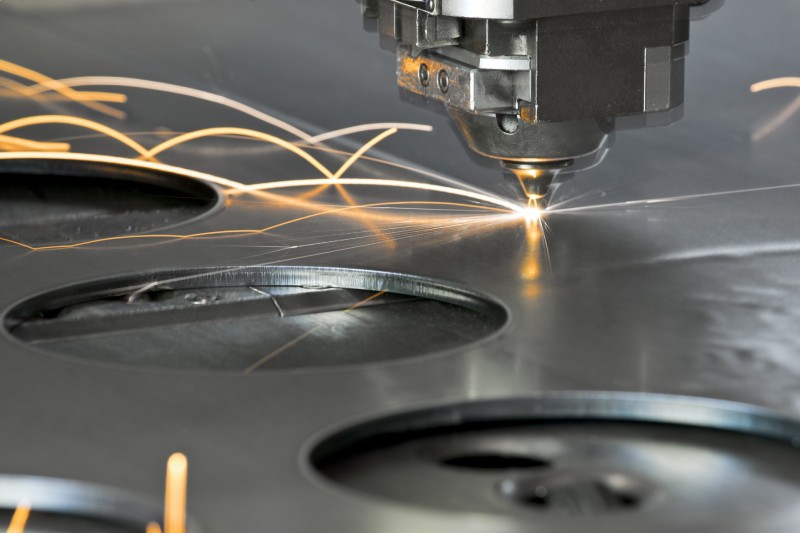

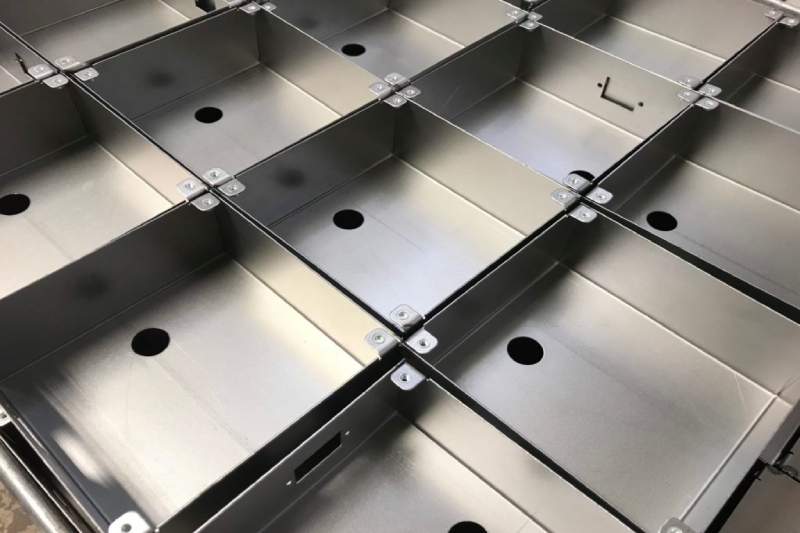

Sheet Metal

We provide comprehensive, tailored sheet metal fabrication services encompassing the entire process, starting from design and extending to manufacturing. Our range of services includes laser cutting, bending, welding, deburring, sanding, hairline polish, laser engrave, clinch insert, rivet and mirror polishing.

We specialize in transforming sheet metals into intermediate metal products, such as meticulously crafted metal piece-parts. To achieve the precise design and specifications requested by our customers, we employ advanced machinery and equipment in a variety of processes. These processes include cutting, bending, welding, deburring, and polishing.

Sheet Metal Capabilities

- FIBER LASER CUTTING

- CNC PRESS BREAK BENDING

- SPOT WELDING

- MICRO LASER WELDING

- TIG & MIG WELDING

- DEBURRING

- HAIRLINE POLISHING

- CLINCHING / PRESS NUT

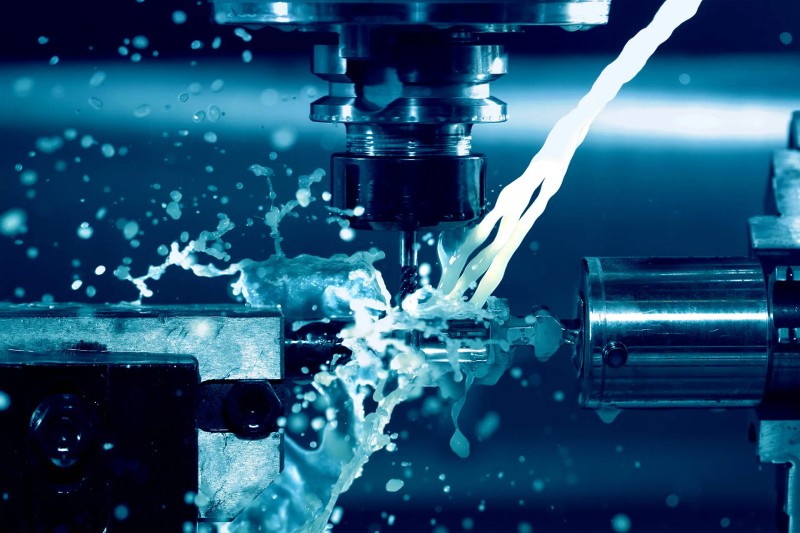

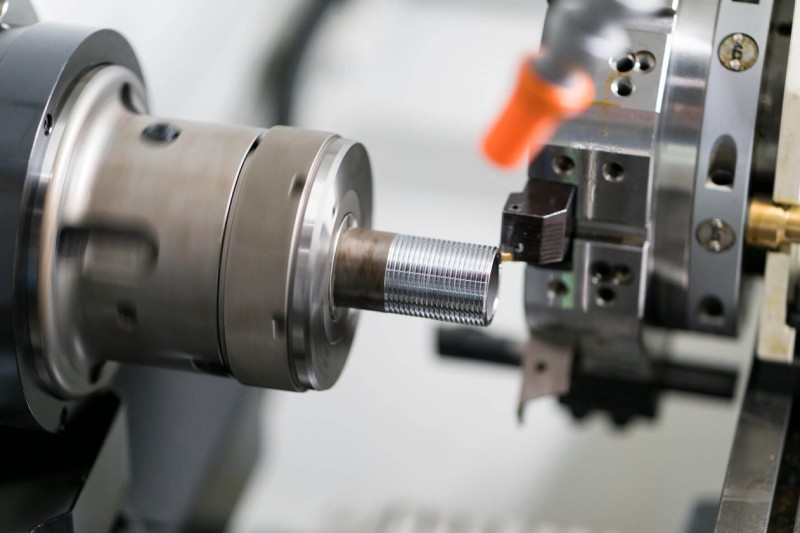

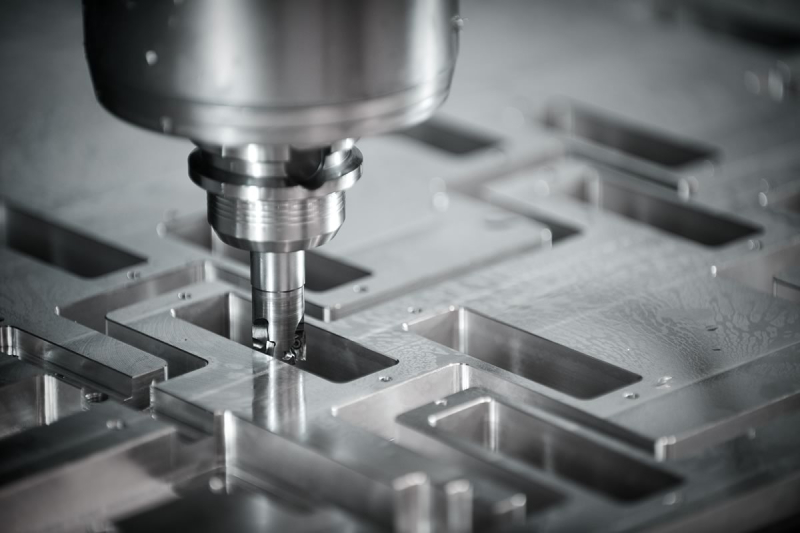

Precision Machining

We firmly believe in the ongoing investment in cutting-edge technology, particularly state-of-the-art CNC MILLING machinery. This commitment serves as a cornerstone of our business, enabling us to provide comprehensive automation equipment solutions as a One-Stop Factory Integration provider. By utilizing advanced machinery, we can efficiently and consistently manufacture CNC machined components to the highest quality standards while reducing production time.

Starting with metal blocks, we employ various processes to transform them into intermediate metal products. These processes involve the removal of excess material to achieve the precise dimensions and specifications required by our customers. Our range of techniques includes milling, turning, surface grinding, and EDM cutting. These processes, carried out with meticulous precision, enable us to produce precision machined components with micron-level tolerances and superior finishes.

Precision Machining Capabilities

- CNC MILLING

- EDM

- TURNING

- SURFACE GRINDING

- TURN MILLING

- CNC WIRECUT

Welding

Welding is a fabrication process that involves joining two or more pieces of metal or thermoplastic materials together by melting and fusing them. It is widely used in various industries, including manufacturing, construction, automotive, aerospace, and more. Welding creates a strong and permanent bond between the materials, allowing for the creation of complex structures and components.

Here are the key points about welding:

- Welding Processes:

- Arc Welding: This is the most common welding process that utilizes an electric arc between an electrode and the workpiece to generate heat and melt the base metals. Common arc welding methods include Shielded Metal Arc Welding (SMAW), Gas Metal Arc Welding (GMAW/MIG), and Gas Tungsten Arc Welding (GTAW/TIG).

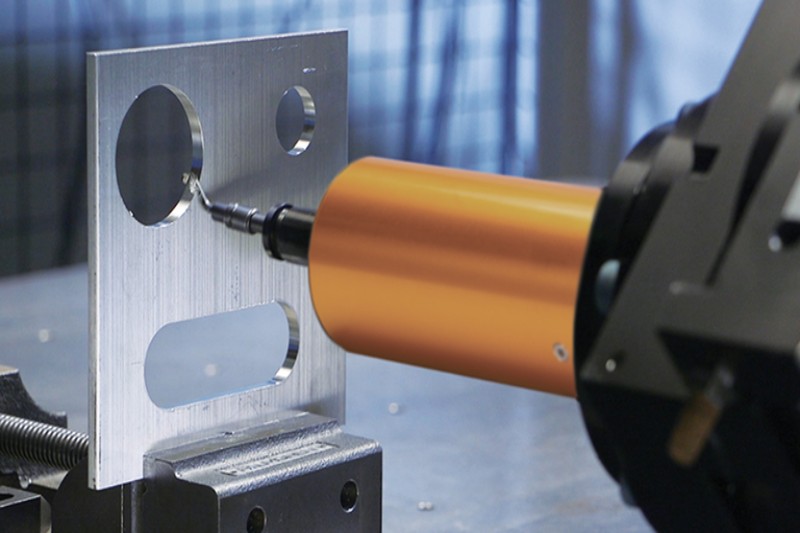

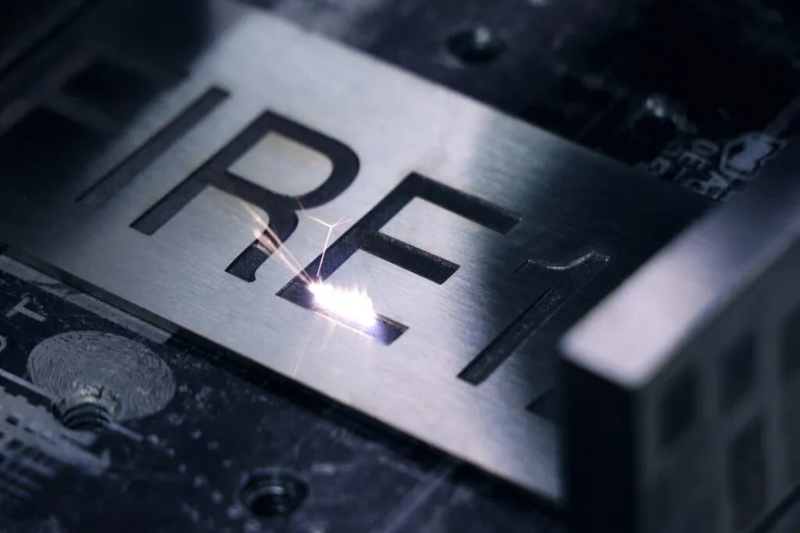

Laser Engrave

Laser engraving is a precise and versatile method of marking or engraving designs, patterns, or text on a wide range of materials using a laser beam. It is a non-contact process that vaporizes or removes the surface layer of the material to create a permanent mark. Laser engraving is commonly used for personalization, identification, branding, artistic, and industrial applications.

Welding Capabilities

- MICRO LASER WELDING

- TIG & MIG WELDING

- SPOT WELDING

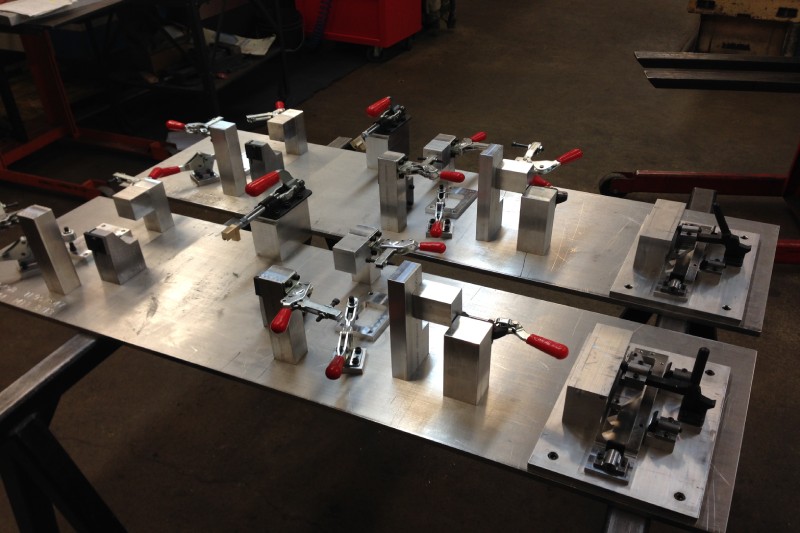

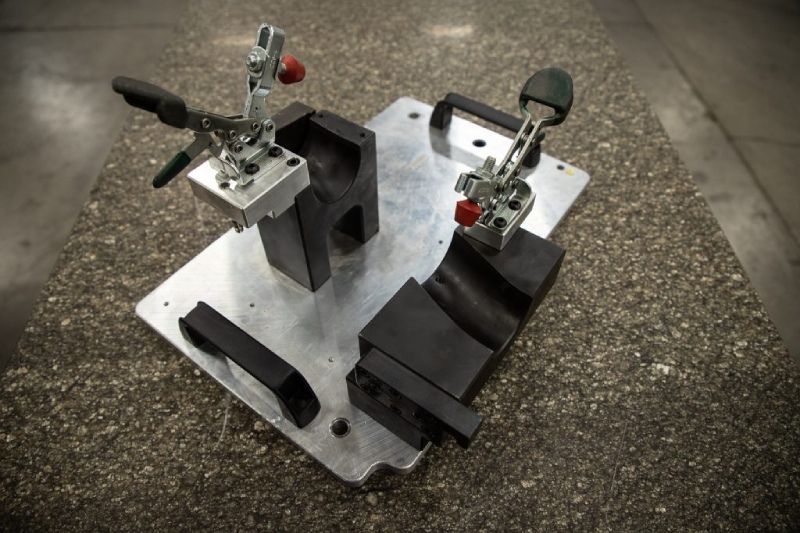

Jig & Fixture

Here’s an overview of jigs and fixtures:

Jigs: A jig is a specialized tool or device that holds and guides a workpiece or tool during a manufacturing process. It ensures precise and repeatable positioning and alignment of the workpiece, facilitating efficient and accurate operations. Jigs are typically used in processes such as drilling, tapping, reaming, and boring.

Fixtures: A fixture is a device used to hold, support, and locate a workpiece during a manufacturing process. Unlike jigs, fixtures do not guide the cutting tools directly but provide a stable and repeatable setup for machining, welding, or assembly operations.

Jig & Fixture Capabilities

- CUSTOM FIXTURE & TOOL BUILD

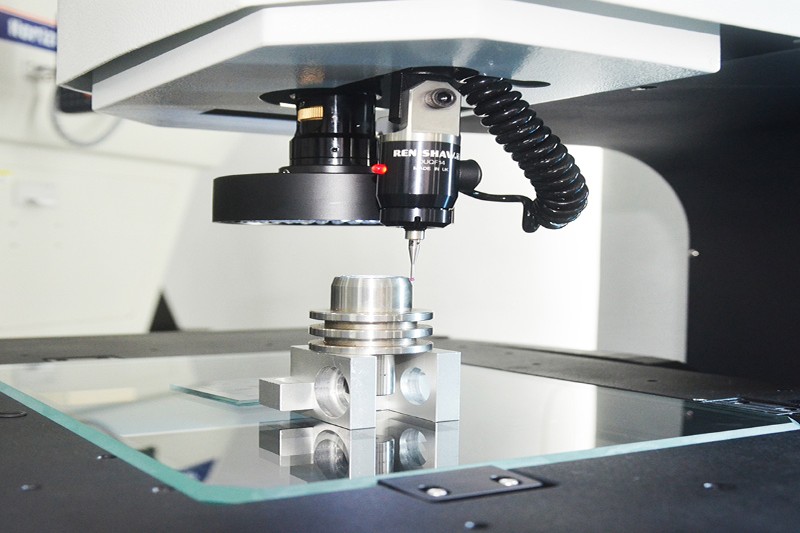

QUALITY INSPECTION EQUIPMENT

Quality inspection equipment refers to a wide range of tools and devices used to assess and verify the quality of products or components. Here are some commonly used quality inspection equipment:

- Micrometers: Micrometers are precise measuring tools used to determine dimensions with high accuracy. Common types include outside micrometers, inside micrometers, and depth micrometers.

- Vision Measuring System: A technology used to measure and inspect various physical objects with the help of computer vision and image processing techniques.

- Coordinate Measuring Machine: It is a versatile tool commonly used in manufacturing and quality control processes to inspect and verify the dimensional accuracy and form of various components.

- Digital Caliper: A measuring tool used to accurately measure linear dimensions of objects with a high degree of precision. It is an upgraded version of the traditional Vernier caliper, offering digital readouts and enhanced ease of use.

- Block Gauge: Also known as a gauge block set or slip gauge set, is a precision measuring tool used for dimensional calibration, inspection, and quality control purposes. It consists of a set of precision ground metal blocks or plates with specific dimensions and tolerances.

FINISHING CAPABILITIES

These processes are performed after the manufacturing or fabrication stage to provide a desired surface finish, improve aesthetics, and protect against corrosion or wear. Here are some common finishing capabilities:

- Chemical Conversion Coating: It involves the application of a chemical solution or coating to the metal surface, which undergoes a chemical reaction to form a protective layer.

- Passivation: It involves the formation of a protective oxide layer on the metal surface, which acts as a barrier against corrosive substances.

- Electroplating / Plating: It involves the use of an electrolyte solution, an electric current, and metal electrodes to achieve the desired plating result.

- Hard Anodizing / Anodizing: It involves immersing the metal in an electrolytic solution and applying a direct current to stimulate the formation of the oxide layer.

- Hard Chrome:The resulting chrome coating provides enhanced hardness, wear resistance, corrosion resistance, and low friction properties.

- Powder Paint: A popular surface finishing process used to apply a durable and decorative coating to a wide range of metal and non-metal substrates.

- Wet Paint: Refers to the application of liquid paint onto a surface for decorative or protective purposes.

- Silkscreen: Is a versatile printing technique that involves using a fine mesh screen to transfer ink onto a substrate.

- Sand / Bead Blast: Is a surface preparation technique that involves propelling small spherical beads at high speed to clean, polish, or texture a substrate.

Contact Us

Let's start talking with us

Testimonial

Feeling of our customers!

"Working with Extreme Metal Technology has been a game-changer for our manufacturing process.

"Extreme Metal Technology has been our trusted partner for several years, and they consistently exceed our expectations.

"We approached Extreme Metal Technology for a complex metal fabrication project, and they delivered exceptional results.

"Extreme Metal Technology has become our go-to metalworking company.

Previous

Next